rockwell hardness test hrc 39|typical rockwell hardness of materials : mail order This results in 30 different Rockwell scales standardized according to ISO 6508 and ASTM E18 (e.g., A, B, C, 30N, 15T) or Rockwell test methods (e.g.: HRA, HRBW, HRC, HR30N, HR15TW), each covering different hardness ranges . Stardust Casino is the online version of the legendary Las Vegas casino that offers you a wide range of games, from slots and live casino to table games and video poker. You can play for real money and earn rewards .

{plog:ftitle_list}

WEB10 de out. de 2022 · O Paris Saint-Germain recebe o Benfica nesta terça-feira, às 16h (horário de Brasília), pela 4ª rodada da Champions League. O duelo vale a liderança do Grupo G, uma vez que ambos estão empatados com sete pontos. ANÁLISE DO 1º JOGO - Precisamos analisar o jogo de ida e ver como o Benfica pode nos colocar em .

Rockwell Hardness (HR) When the Brinell hardness (HB) exceeds 450 or the sample is too small, the Rockwell hardness test is used instead. This test involves pressing a diamond cone with a 120° top angle or a .

This table shows approximate hardness of steel using Brinell, Rockwell B and C and .

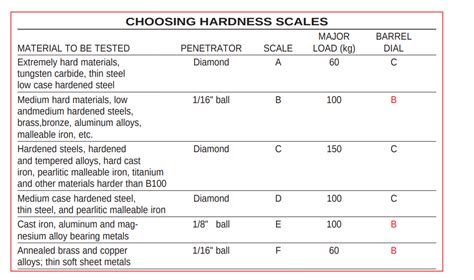

While the Rockwell hardness testing scale is prevalent, it is best to consider the material thickness and softness to select the most suitable scale between Rockwell B (HRB) .Rockwell Hardness Testing Reference Guide ASTM E18 contains a listing of all regular Rockwell scales and typical materials for which these scales are applicable. Use these tables in selecting the scale that is appropriate for your .This results in 30 different Rockwell scales standardized according to ISO 6508 and ASTM E18 (e.g., A, B, C, 30N, 15T) or Rockwell test methods (e.g.: HRA, HRBW, HRC, HR30N, HR15TW), each covering different hardness ranges .

Rockwell Hardness HRC Scale Definition. The defined values of preliminary test force and total test force are the SI equivalents of the original Rockwell hardness method-defined forces of 10 . To calculate Rockwell hardness C number: Multiply scale factor, 500, by depth of penetration, d. Subtract the product from the scale factor 100 to obtain the Rockwell hardness (HRC) number. Mathematically, that's: HRB = .Rockwell C Hardness Conversion. Approximate Conversion Numbers for Non-austenitic Steels. Rockwell. Superficial Rockwell. Brinell. Vickers. Knoop. Tensile Strength. Diamond Penetrator.Principle of Test. The Rockwell test consists of measuring the additional depth to which a carbide ball or Brale® diamond penetrator is forced by a heavy (major) load beyond the depth .

typical rockwell hardness of materials

While the Rockwell hardness testing scale is prevalent, it is best to consider the material thickness and softness to select the most suitable scale between Rockwell B (HRB) and Rockwell C (HRC). . Can you Convert HRB to HRC? Converting hardness Rockwell B (HRB) to hardness Rockwell C (HRC) is a usual practice for many designers when .Rockwell testing falls into two categories: Regular Rockwell testing (e.g., C and B scales) and Rockwell superficial testing (e.g., 30 N and 30 T scales). High Rockwell hardness numbers represent hard materials and low numbers soft materials. d 2 www.wilsoninstruments.com Fundamentals of Rockwell Hardness Testing In Rockwell hardness testing, HRA, HRB, and HRC represent three different scales: Scale A, Scale B, and Scale C. The Rockwell test is a common indentation hardness test. All three scales begin with an initial .

rockwell hrc scale chart

The Rockwell scale was cocreated by Hugh and Stanley Rockwell in the early 20th century to test the hardness of different materials. There are several different scales by which a material’s hardness is measured on, but blade steels are measured on the C scale. (HRC means Hardness on Rockwell scale C.)Rockwell Hardness Testing Reference Guide ASTM E18 contains a listing of all regular Rockwell scales and typical materials for which these scales are applicable. Use these tables in selecting the scale that is appropriate for your application. Regular Rockwell Testing. In this test method, the minor (preload) is always 10 kgf. .

The connection between hardness and carbon content is clearly visible in the example below: the higher the carbon content, the higher also the HRC of various types of White Steel: White Steel 1 / 63 HRC / C = 1.25-1.35 % White Steel 2 / 61-62 HRC / C = 1.05-1.15 % White Steel 3 / 60 HRC / C = 0.80-0.90 % Measuring hardness There are several .In the Rockwell hardness testing, the indenter applies the first load to the test piece. The indent is then measured, and the value obtained is used for the base calculations. This first load is removed, and another heavier load is applied to the indenter on the test piece. . Example 1: A regular Rockwell hardness method (HRC) 45 HRC. The .

The test procedure for the Rockwell hardness test is covered in the standard document ISO 6508 for metallic materials and ISO 2039-2 for plastics. The overall procedure is similar to other indentation tests. . Subtract the product from the scale factor 100 to obtain the Rockwell hardness (HRC) number. Mathematically, that's: HRB = 100 - 500 × d.Brinell [HB] is one of the most common units used for listing the hardness of steel materials. The test is done with a 10 mm steel ball pressed with 3000 Kgf (6,614 Lbf). Common values for machined materials range from 100 HB for very soft materials up to 650 HB for heat-treated steels.. The advantage of Brinell [HB] over Rockwell [HRC/HRB], is that the whole range is .What is Rockwell hardness testing? The Rockwell Hardness Test is generally a non-destructive test performed on samples when it’s necessary to determine how hard a material is. It’s generally considered easier to perform compared to other methods, like Vickers or Brinell hardness testing. Another advantage is the small area of indentation needed to carry out the .

Conversion table/chart for Brinnel and Rockwell hardness scales and tensile strengths. Buy metals and plastics online in small quantities, cut to order.The Rockwell hardness test is less affected by surface rough-ness compared to other methods such as the Vickers or Brinell tests. It can provide reliable hardness measurements even on . 150 kg HRC HRGW HRKW HRPW HRVW 100 kg HRD HRBW HREW HRMW HRSW 60 kg HRA HRFW HRHW HRLW HRRW 45 kg (Superficial) HR45N HR45TW HR45WW HR45XW HR45YWRockwell hardness test measures the permanent depth of indentation on the material by applying a fixed load using an indenter. The smaller the indentation value, the harder is the material. The Rockwell hardness test follows the principle of the differential-depth method. Here, the indenter makes a residual depth called the indent and it is .

When the Brinell hardness test cannot be used, such as when the material’s HB value is greater than 450 or the sample size is too small, the Rockwell hardness test is used instead. This test involves pressing either a diamond cone with a top angle of 120° or a steel ball with a diameter of 1.59 mm or 3.18 mm into the surface of the tested . HV, HB, HRC Hardness Comparison Chart. Hardness testing is the simplest and most straightforward method among mechanical property tests. In order to replace certain mechanical property tests with hardness tests, a . In the Rockwell hardness test, an indenter is pressed into the material. The indentation depth serves as a measure of the hardness! In the Rockwell hardness test, the measure of the hardness is not an indentation .

2001 toyota camry compression test

Worldwide service network | 1-800-473-7838 service@buehle r.com Providing service and support that is dedicated to ensuring the highest quality

Related reading: Metal Hardness Comparison Chart: HV, HB, HRC Commonly Used Hardness Brinell Hardness. The Brinell hardness test uses a ball made of hardened steel or a hard alloy with a diameter of D as the indenter.. A specified test force F is applied to the surface of the material being tested, and after a designated hold time, the test force is .Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load). . HRB, HRC, etc., .That’s why these standards formulate tables for conversion process, with test load and hardness ranges. Here are the hardness tables and conversion charts for you. + 86 755 61301520

Digital rockwell hardness tester adalah alat ukur digital yang membantu teknisi dalam megukur bahan konstruksi. . Perbedaan dalam Mengukur HRC dan HRB dengan Digital Rockwell Hardness Tester – . [email protected]; 0857-1711-2222; Layanan Pelanggan. e-Katalog; Kebijakan Privasi;

No, 60 HRC is significantly harder than 45 HRC. The Rockwell hardness scale is linear, so higher numbers indicate greater hardness. A material with a hardness of 60 HRC is much harder and more resistant to deformation than a material with 45 HRC. . What are the disadvantages of Rockwell? The Rockwell hardness test can be influenced by surface . BHN to HRC Conversion Convert to HRC This article is here to make things simple for metalworkers. It offers a handy tool for converting Brinell Hardness Number (BHN) to Rockwell C Hardness (HRC). Knowing about hardness scales like Rockwell, Brinell, and Vickers is key in the metalwork field. We'll talk about why hardness matters in machining.

ROCKWELL HARDNESS TESTING MACHINES TEST EQUIPMENT HR-300/400/500 SERIES AND SEISMOMETERS. Rockwell Hardness Testing Machines to suit . 1/16" Carbide Ball Indenter Hardness test Block 60 HRC Hardness test Block 60 HRC AC Adapter Hardness test Block 30 HRC Hardness test Block 30 HRC

Reference Table: Steel hardness conversion chart - all values approximate. Brinell Hardness HB Rockwell HRC Rockwell HRB Vickers HV N/mm²; 800: 72---780: 71 This test uses different materials for the indenter. Hence, the varying scales ranging from A-V. For straight razors, we use HRC, which is again the c-scale of Rockwell Hardness. An HRC test is done by utilizing a spheroconical diamond as an indenter while enforcing a preliminary force of 10kgf and a total force of 150 kgf.

1.1 These test methods cover the determination of the Rockwell hardness and the Rockwell superficial hardness of metallic materials, including test methods for the verification of machines for Rockwell hardness testing (Part B) and the calibration of standardized hardness test blocks (Part C).

rockwell hardness test explained

27 de ago. de 2023 · Com o resultado, o Grêmio assumiu a terceira posição na tabela de classificação, com 36 pontos somados, e voltou ao G4. Já o Cruzeiro está na 12ª .

rockwell hardness test hrc 39|typical rockwell hardness of materials